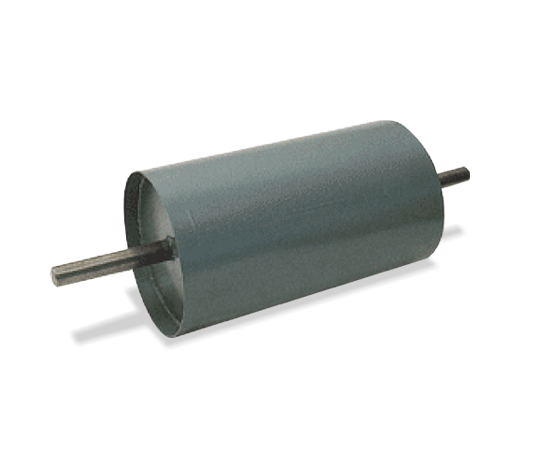

Magnetic Pulley

Automatic Conveyor Metal Separation System

Ideal for continuous extraction of ferrous contaminants from conveyor belt material flow.

The Magnetic Pulley is engineered to replace the existing head pulley of a conveyor system, enabling continuous, automated separation of iron contaminants from bulk-flowing materials. As material passes over the magnetic pulley, ferrous particles are captured and removed without disrupting production.

Available in Ferrite and Rare-Earth NdFeB models, Magnetic Pulleys offer reliable performance in industries requiring durable, high-strength magnetic separation for improved product purity and equipment protection.

Technical Specifications

| Specification | Details |

|---|---|

| Pulley Diameter | 150 – 600 mm |

| Pulley Width | 300 – 1800 mm |

| Magnet Type | Ferrite / Rare Earth NdFeB |

| Shell Material | Stainless Steel |

| Belt Speed | 50 – 100 MPM |

| Working Mode | Continuous Automatic Operation |

| Surface | Rubber Lagging (Optional) |

| Ideal Installation | Conveyor discharge point |

Key Features

- Continuous inline metal separation

- Highly efficient magnetic field penetration

- No stoppage required during operation

- Fits standard conveyor systems

- Robust stainless-steel construction

- Available in multiple diameter & width options

- Low power consumption

Advantages

- Eliminates ferrous contamination without manual labor

- Prevents equipment wear & breakdown

- Enhances product purity & recovery value

- Suitable for both light & heavy-duty usage

- Works with wet, dry & dusty materials

Applications

- Stone Crushing & Mining: Stone chips, minerals, sand

- Cement & Coal: Clinker, fly ash, coal

- Glass & Ceramics: Silica, quartz

- Recycling Plants: Scraps, waste, rubber & plastic

- Food & Grain: Bulk solid materials handling